Back to overview

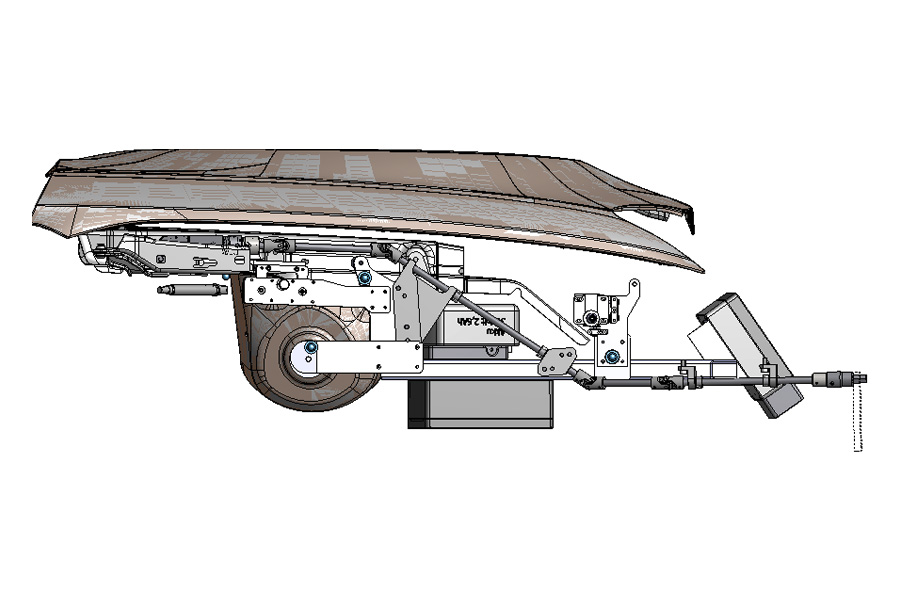

Tailgate

What is fastened?

- The hinge between the the tailgate and the chassis

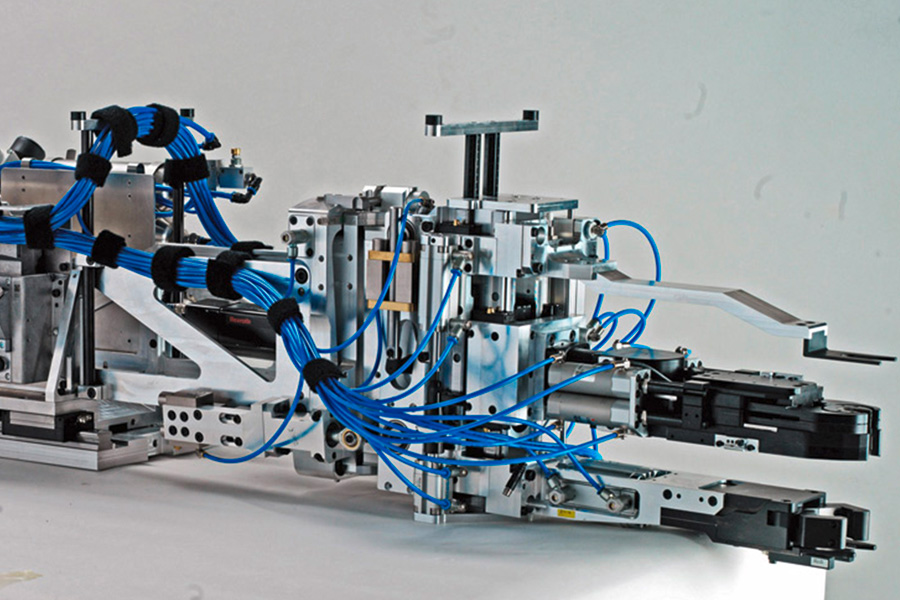

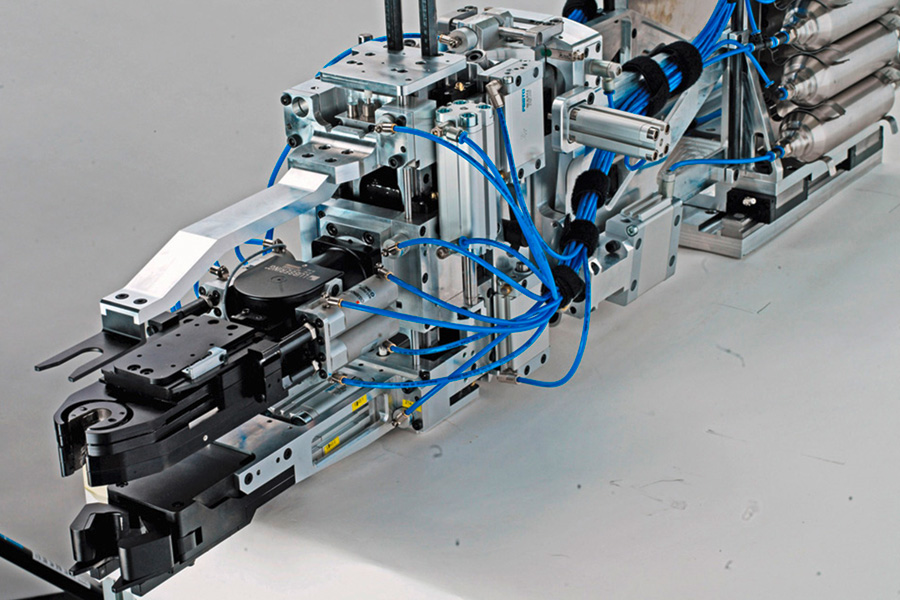

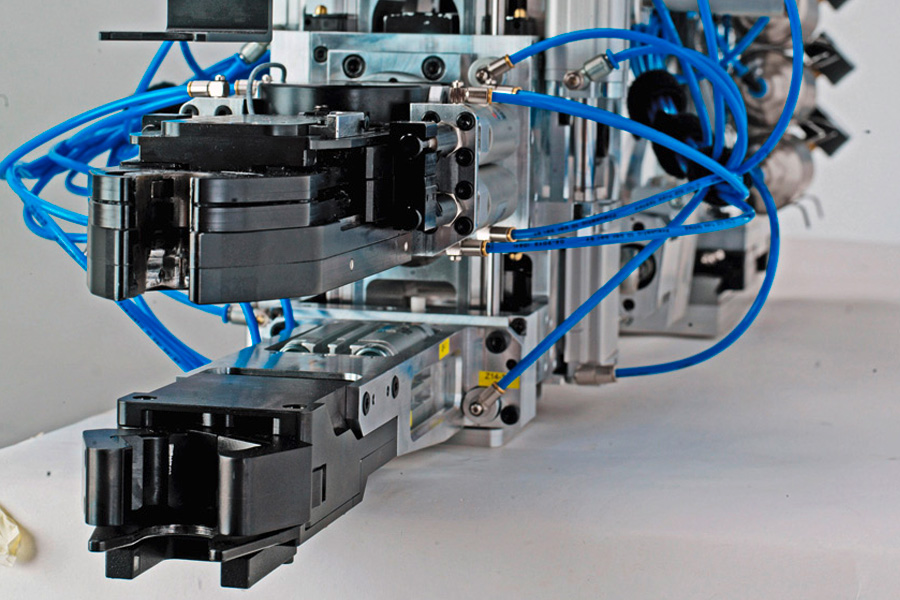

What are the difficulties?

- The tailgate has to be fastened to the chassis in the closed position

- Parallel fastening in very tight space and high torque

- Complete fastening system including drives, fasteners

- The start must be actuated externally

What is Lübbering‘s solution?

- Synchronised fasteners which are remotely and centrally controlled but separately fastened through pre-tightened torque

- Designing a fastening system which includes drives, gears and torque shutoff

Back to overview

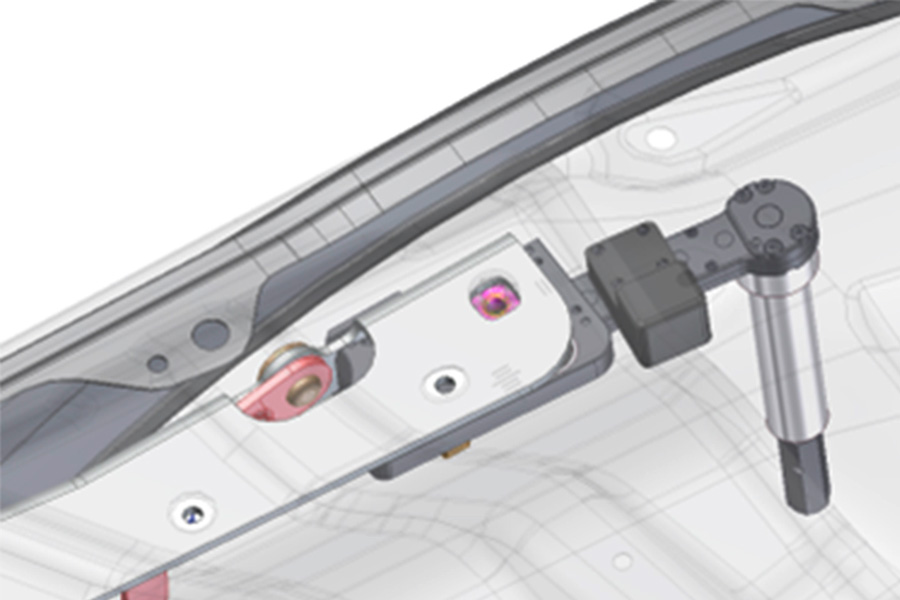

Brake line

What is fastened?

- (A) Hydraulic brake line at Porsche 911 and Porsche Boxter

- (B) The brake line in the front and rear wheel arches at Porsche Cayenne

- (C) Fastening on the underside of the car

What are the difficulties?

- (A) The access is difficult and tight space

- (B) Poor visibility for the worker and safe fastening: A-fastening

- (C) Holder is essential | the fastener must be held in position, as it cannot be attached to the car

What is Lübbering‘s solution?

- (A) 4-stage Inline geared offset head for best access to the fastening application in combination with an Atlas Copco EC-Tool which will provide the correct torque

- (B) The smallest possible geared offset head with maximum performance and high repeatability

- (C) The separation point is fastened in one step with an open geared offset head with a sliding holder

Back to overview

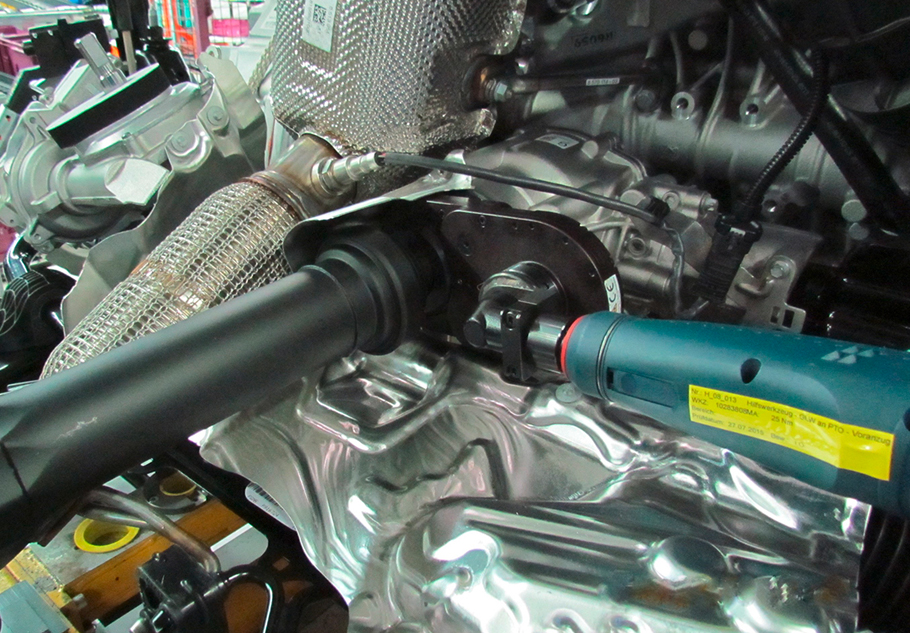

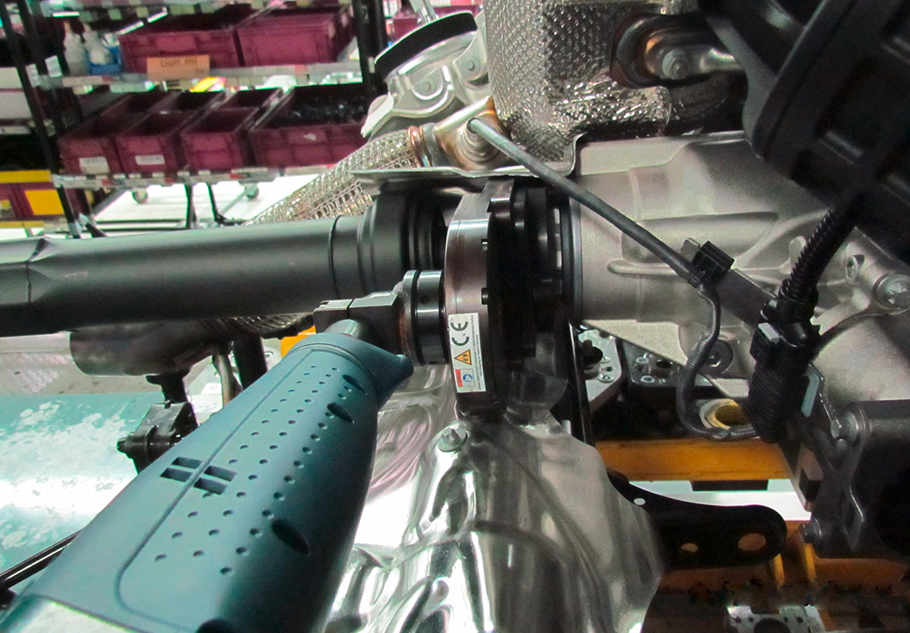

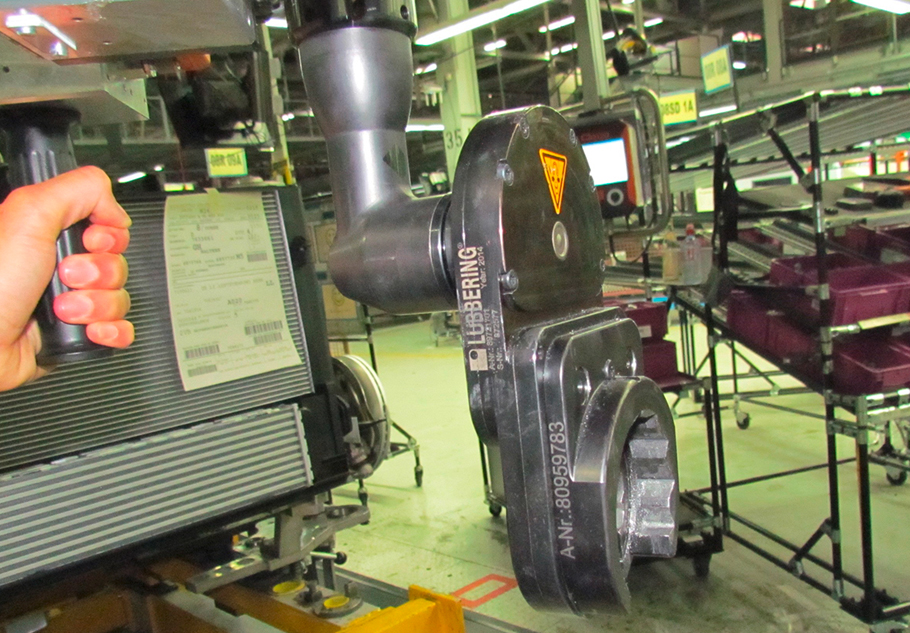

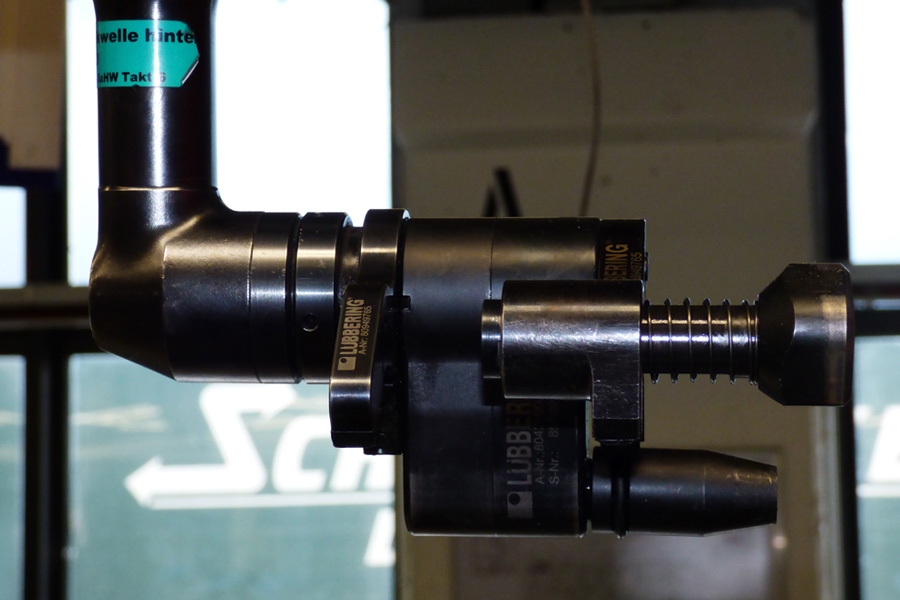

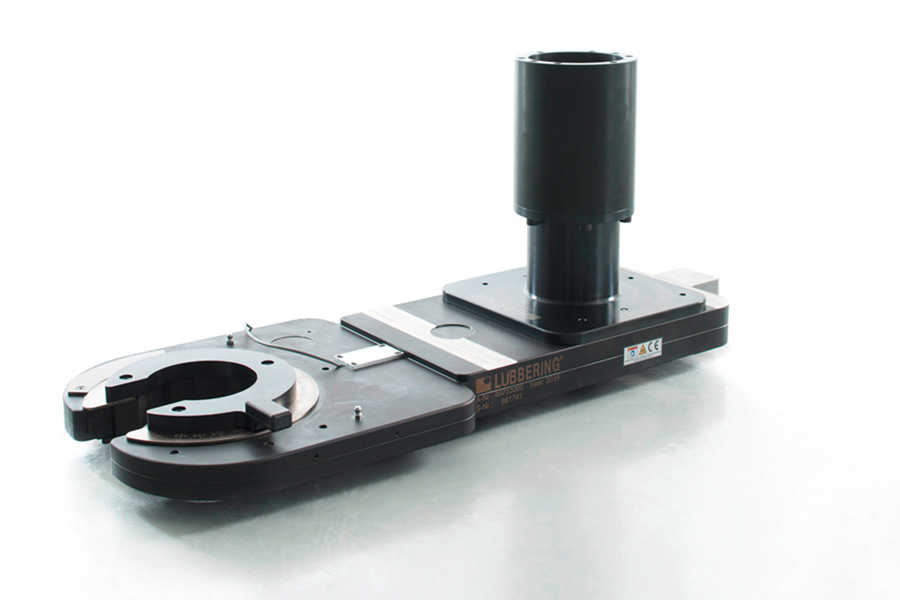

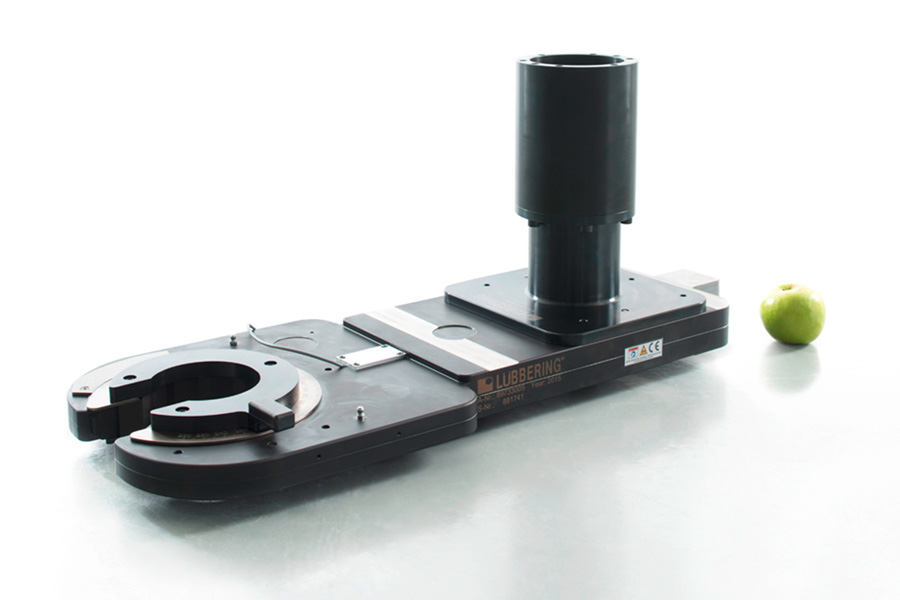

Cardan shaft

What is fastened?

- Cardan shaft flange in the front and back

What are the difficulties?

- Reinforcing and centering the torque on the cardan shaft

What is Lübbering‘s solution?

- 2 variants for cardan shafts for the front and back

- Geared offset head with swivelling holder which avoids the twisting of the cardan shaft when applying the torque

- Additionally, the machine operator can keep on turning the cardan shaft with the fastening system to reach the next fastening position

Back to overview

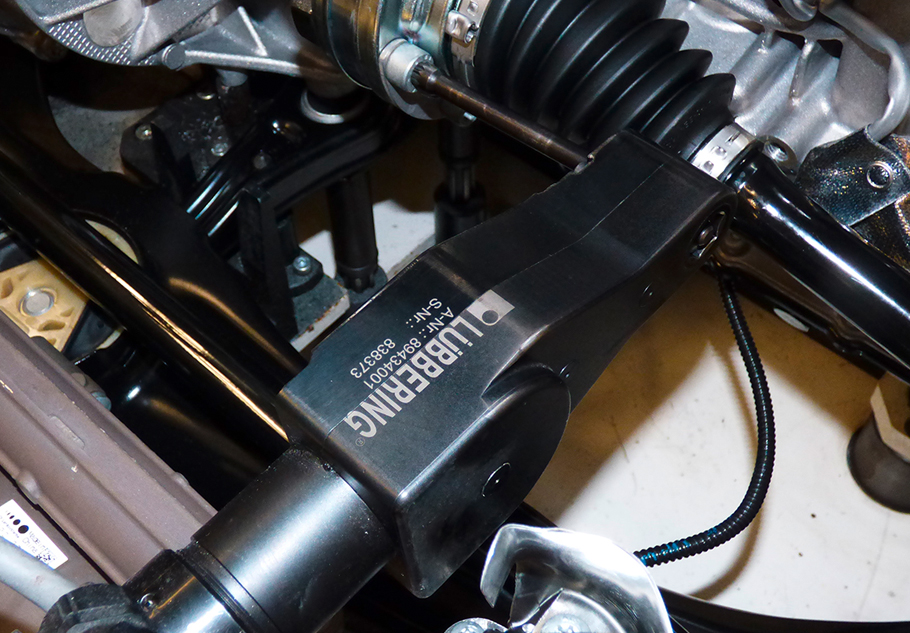

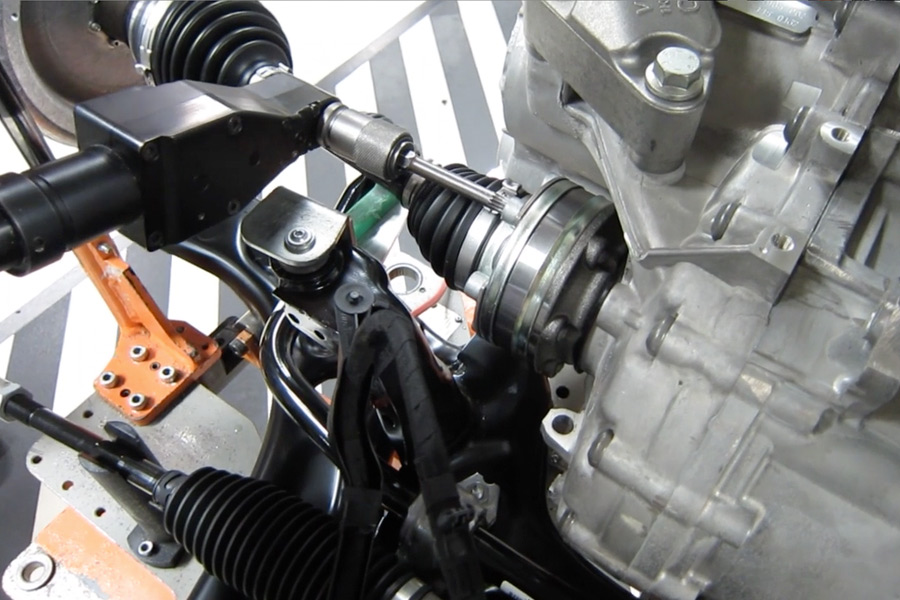

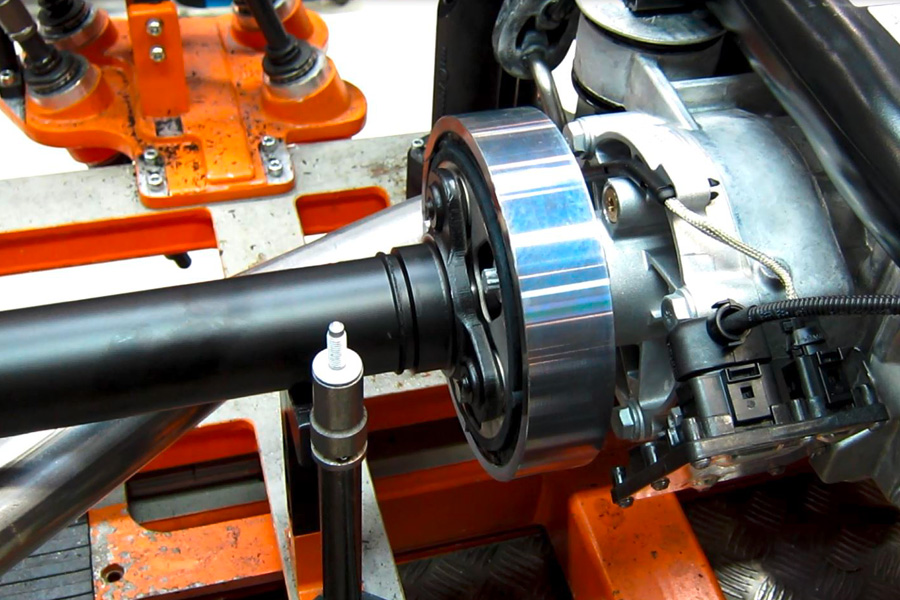

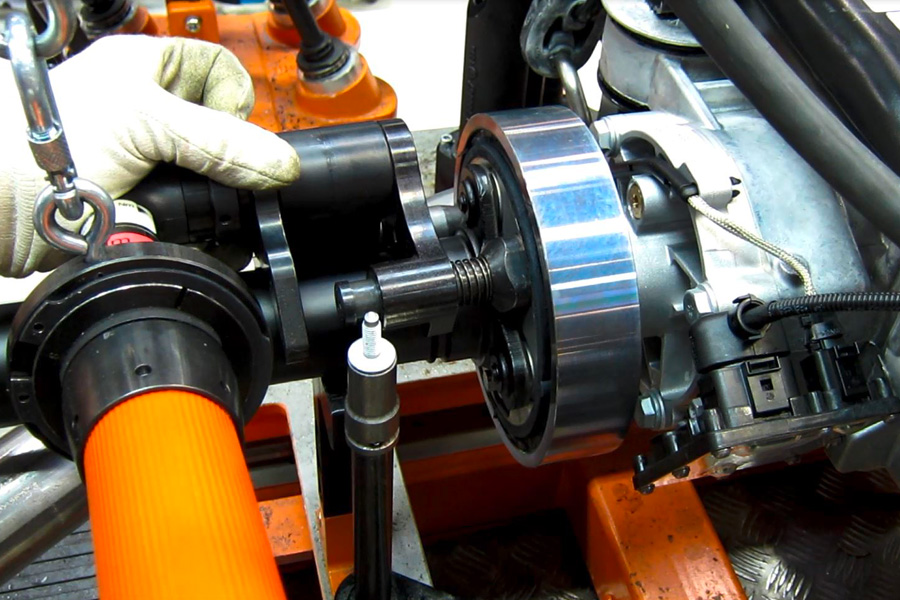

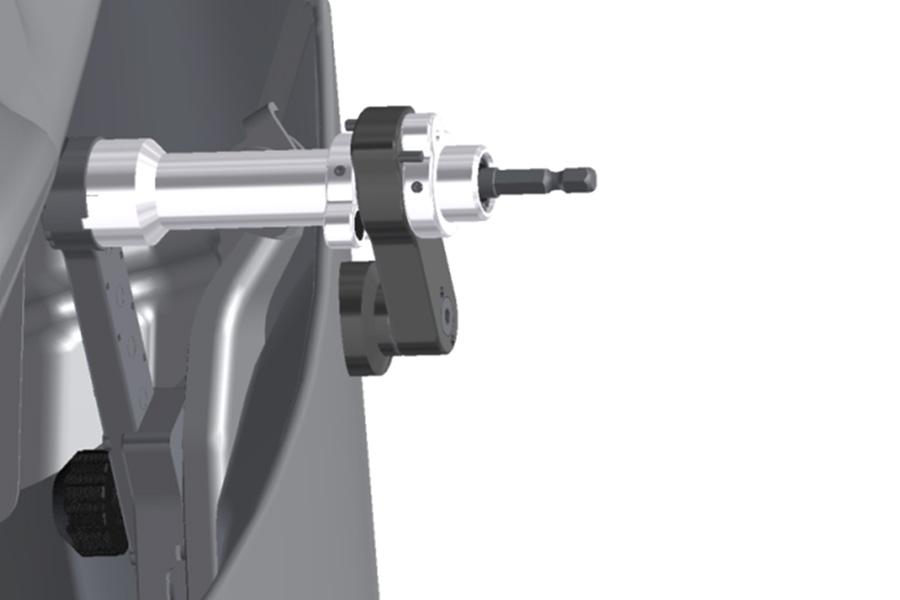

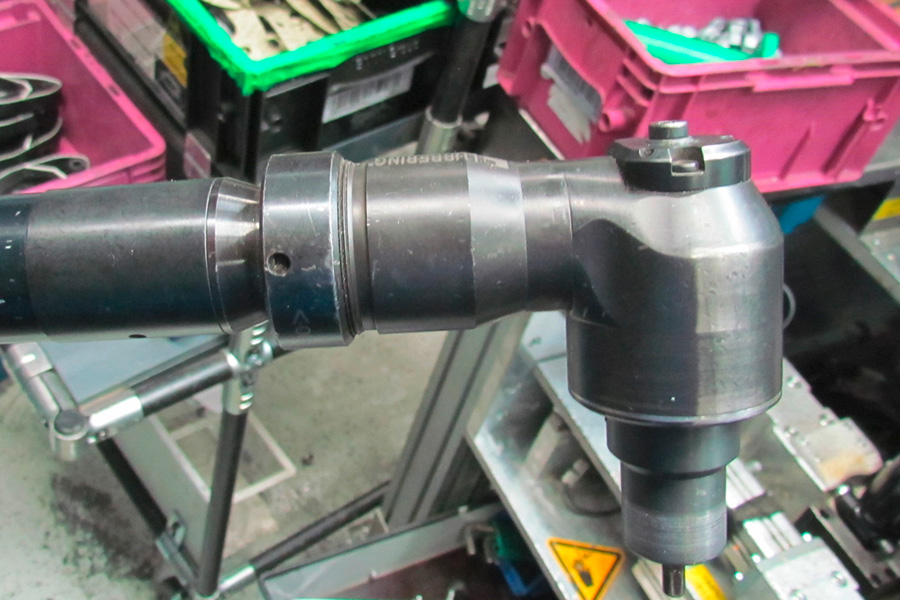

Drive shaft

What is fastened?

- (A) The central screw on the cardan shaft

- (B) Flange cardan shaft (is fastened to the gearbox with several (6 to 8) fastenings per side)

What are the difficulties?

- (A) Central nut with extrem large width across flats | the nut is fastened to the left | Accuracy required by the customer: +/- 10 %

- (B) Critical fastening access and angle fastening with high end torque

What is Lübbering‘s solution?

- (A) Open geared offset head with holder (A/F 50 / A/F 64) | Accuracy of the geared offset head: +/- 7,22% | capable of 100 Nm

- (B) Inline geared offset head with insert for bit extension to improve access | output torque of 100 Nm at minimal radius

Back to overview

Track setting

What is fastened?

- Steering track-rod

What are the difficulties?

- Track-rod must be removed, adjusted and refastened

- Two different track-rods with different widths across flats

- Consistent, lasting accuracy during the process is required

What is Lübbering‘s solution?

- Complex special design of the track setting tool

- Opened geared offset head with a multiple function output socket gear

- To achieve a „swimming“ installation of all components to ensure operation from every angle

Back to overview

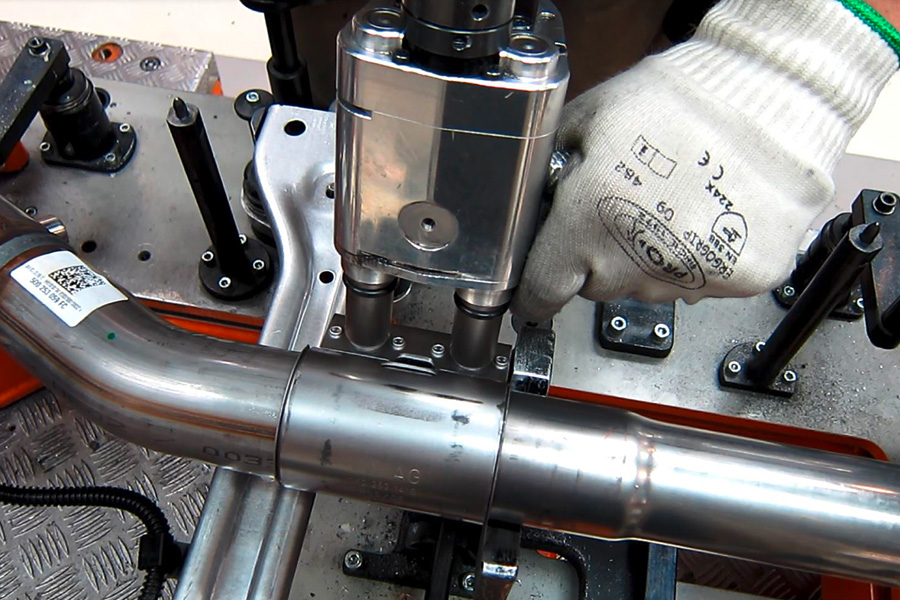

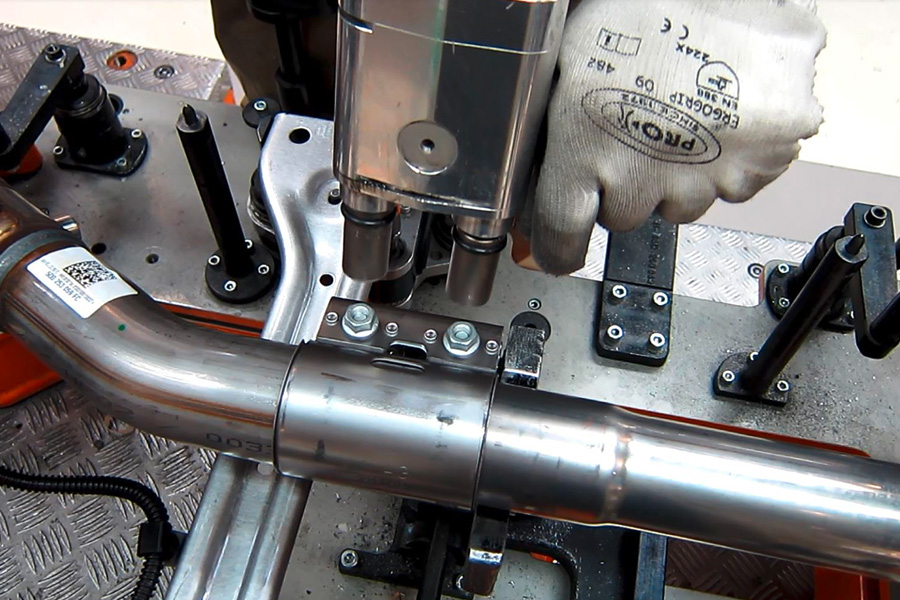

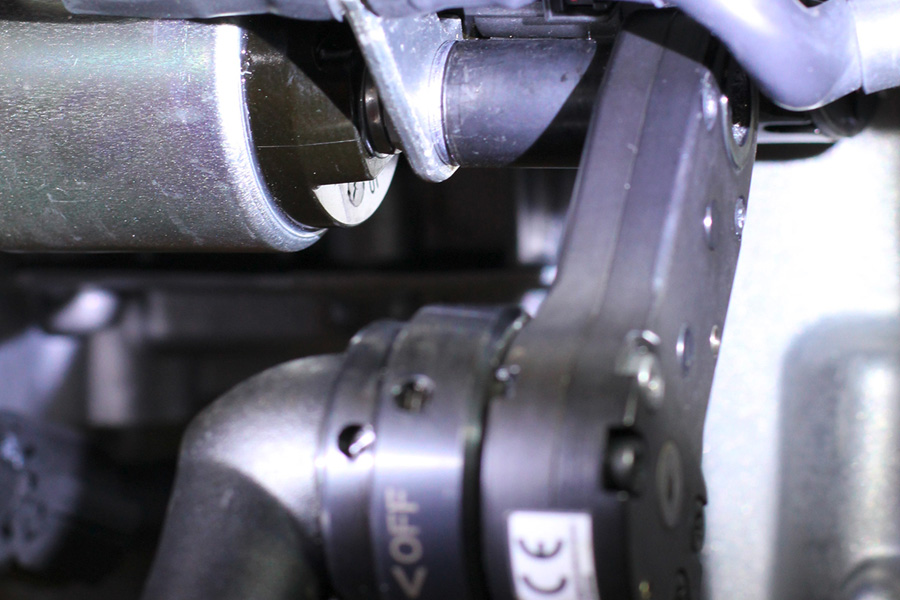

Exhaust system

What is fastened?

- Clamps on the exhaust system with two screws

What are the difficulties?

- Fastening both screws simultaneously

- One tool has to drive two outputs (torque must be 50-50)

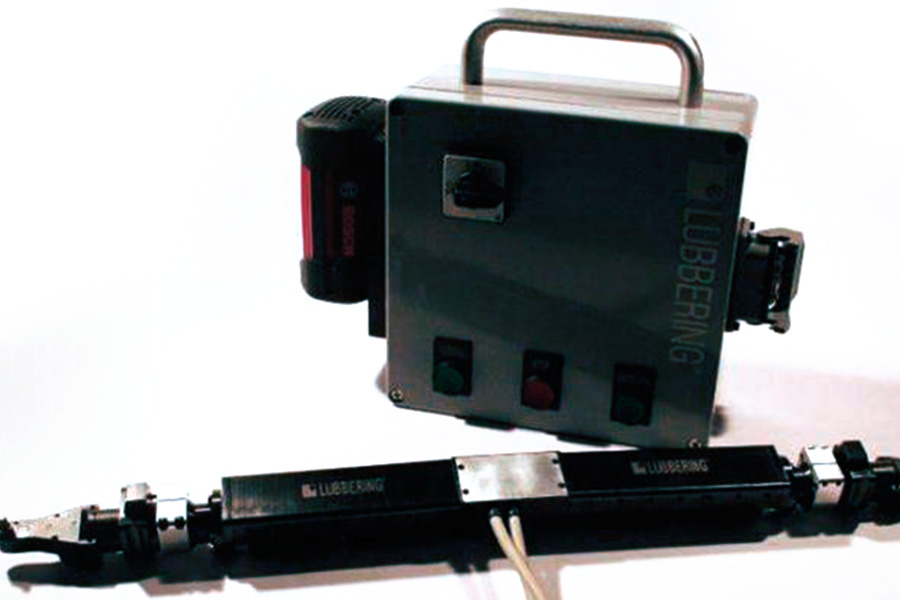

What is Lübbering‘s solution?

- Complete redesign of the differential gear

- Special fastening system with differential gear

Back to overview

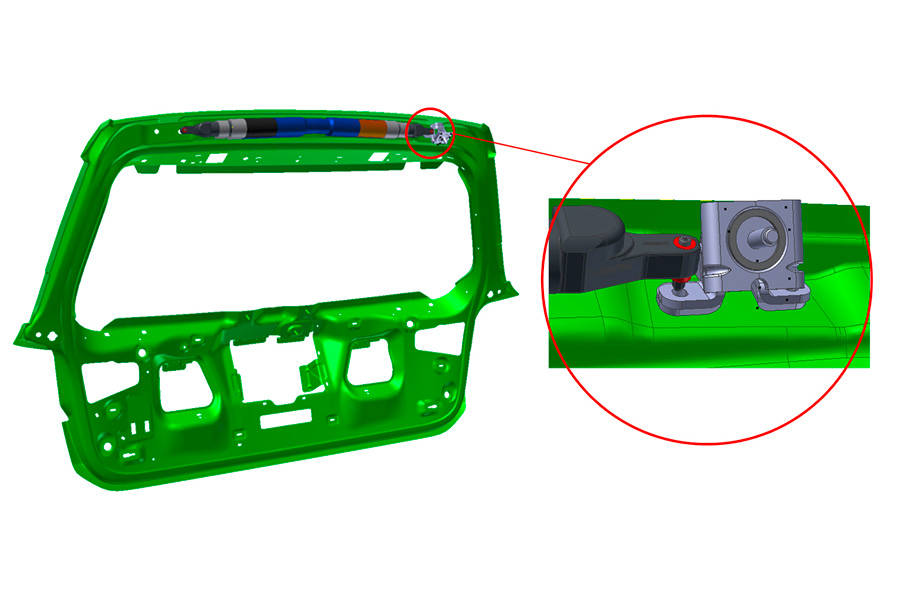

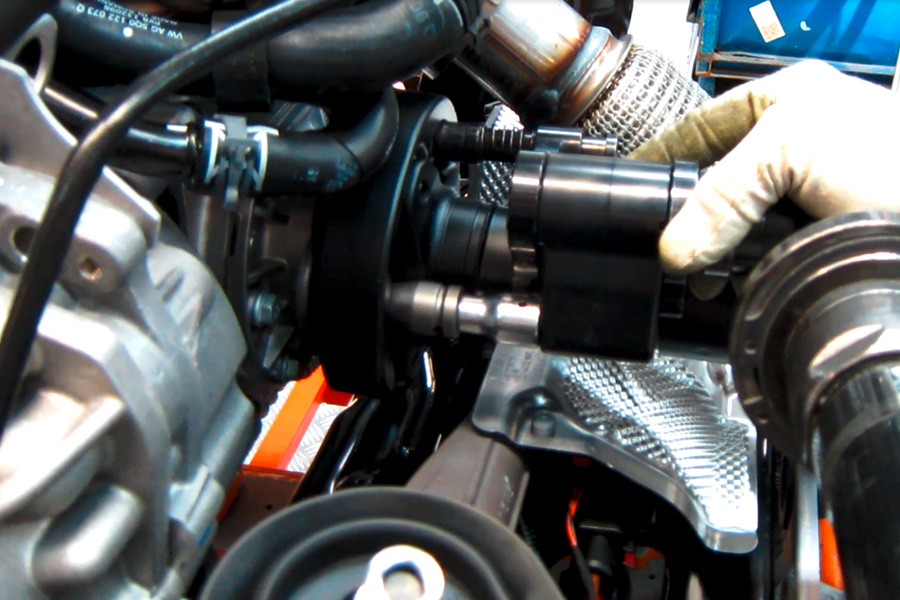

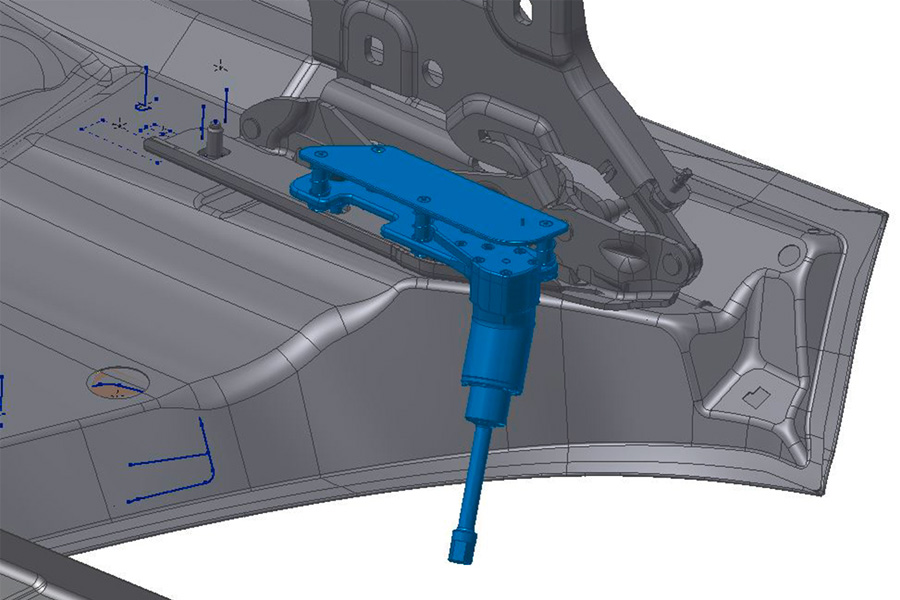

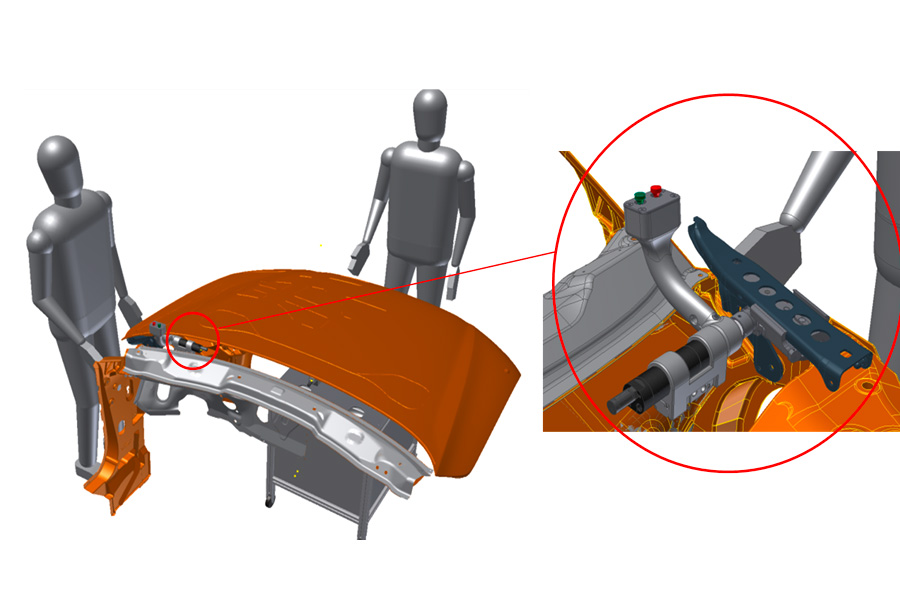

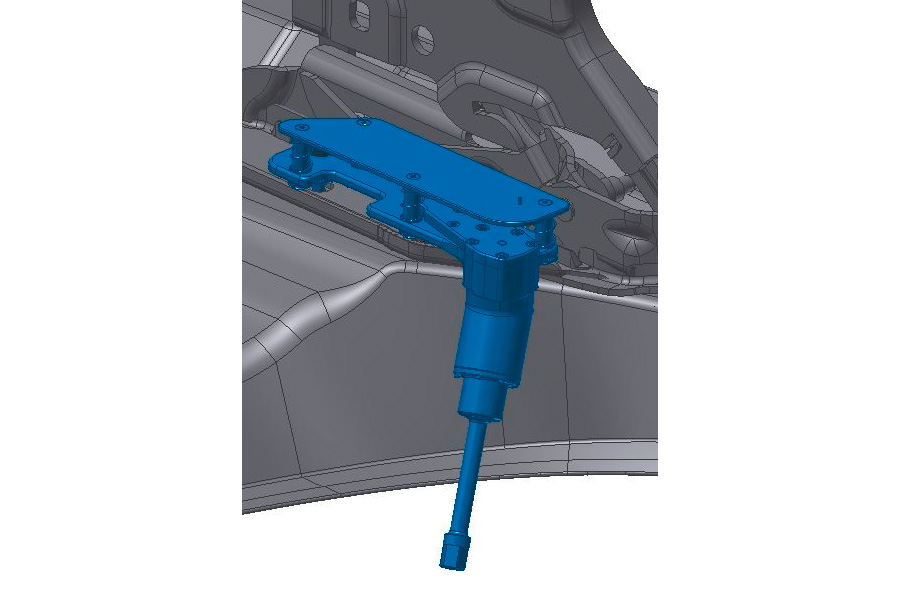

Front flap

What is fastened?

- The front flap at the hinge

What are the difficulties?

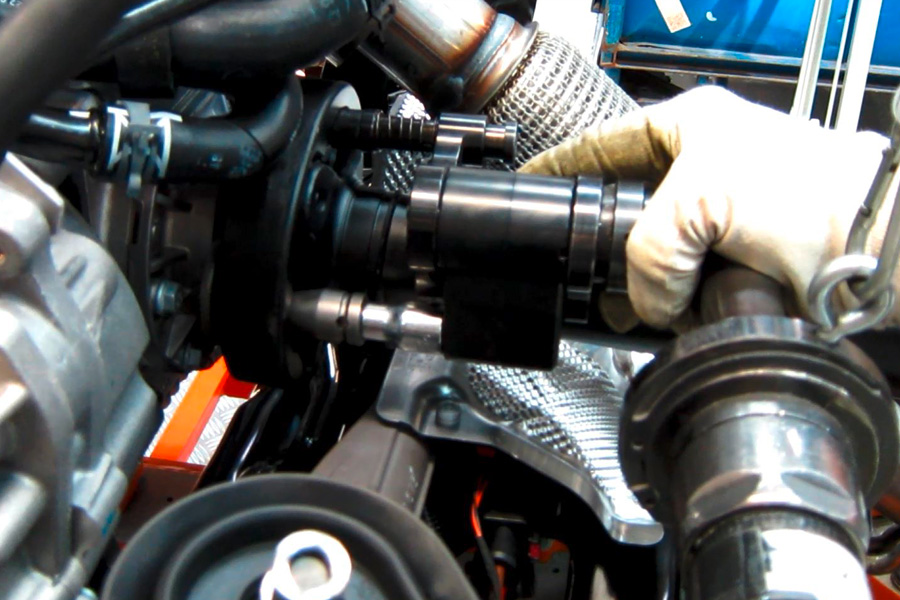

- Critical access in the engine block

- Has to be fastend in closed room due to gap measurement

What is Lübbering‘s solution?

- Fastening sytsem consisting of Special-Line, adapter, output socket, nut, drive motors and control system

Back to overview

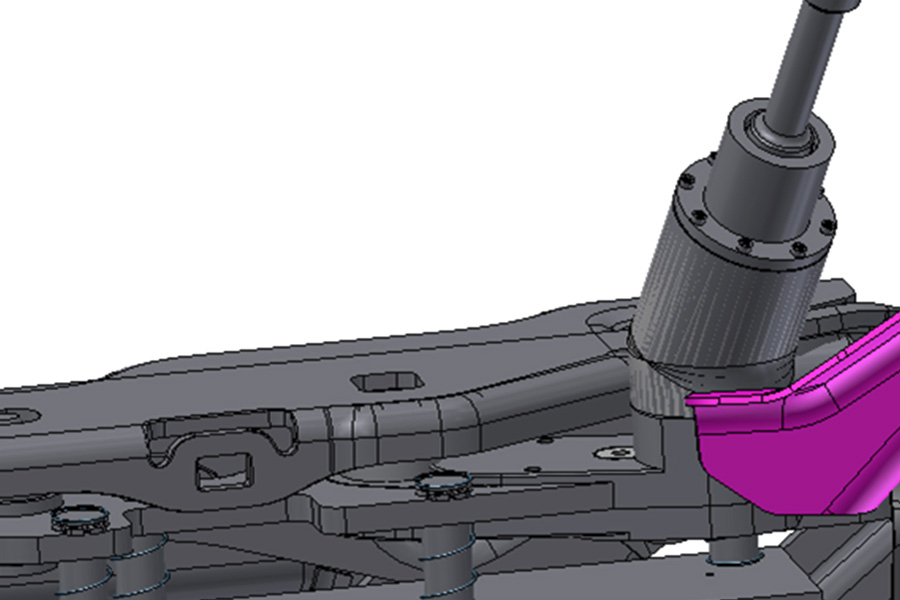

Roll stabiliser

What is fastened?

- The central screw on the roll stabiliser

What are the difficulties?

- Large widths across flats (82mm & 110mm)

- Readjustment of the output socket profile through an adjustment ring must be possible

- The fastening process takes places on a measuring bench

- The geared offset head housing must also serve as a measuring tool

What is Lübbering‘s solution?

- Opened geared offset head with an output torque of 500 Nm

- Measuring scale on the output socket gear

Back to overview

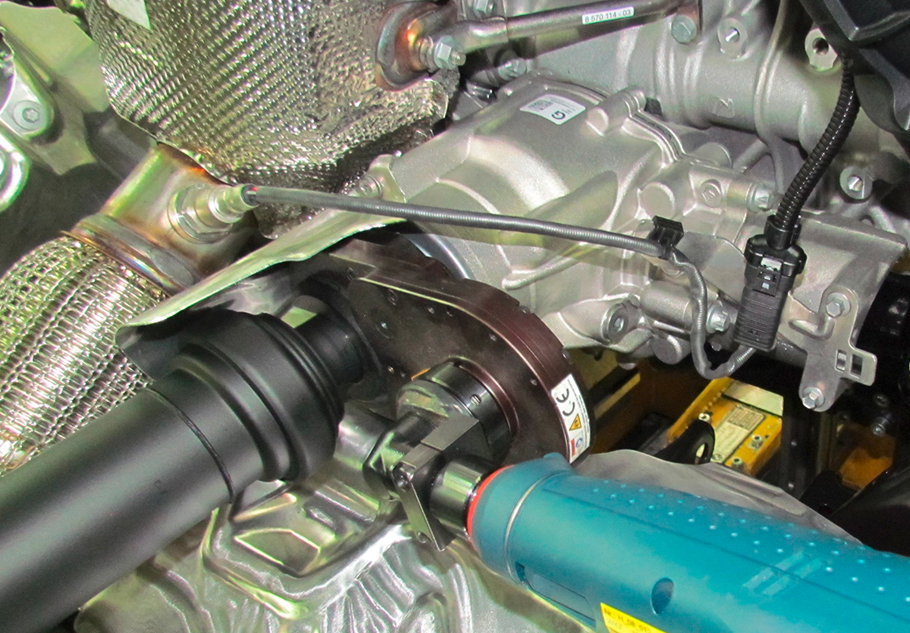

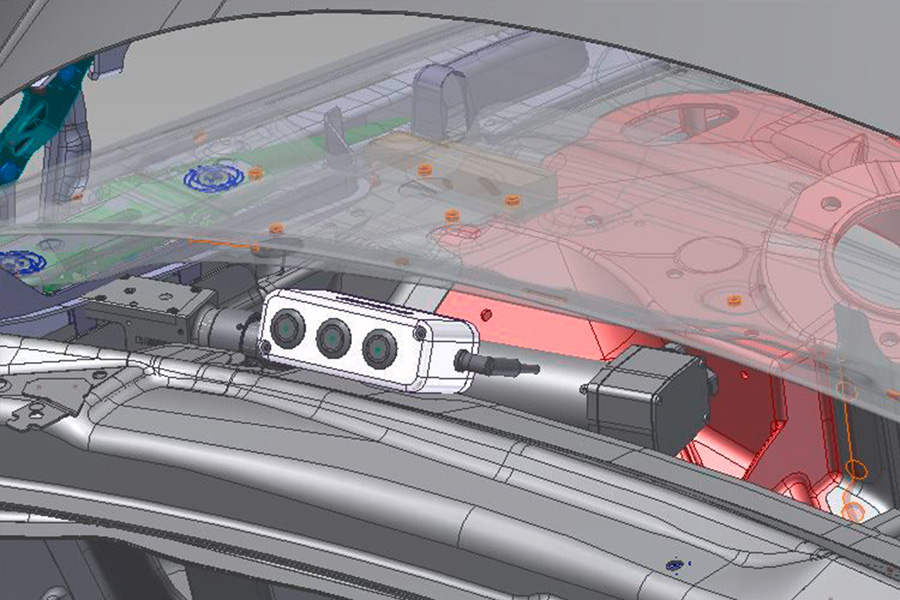

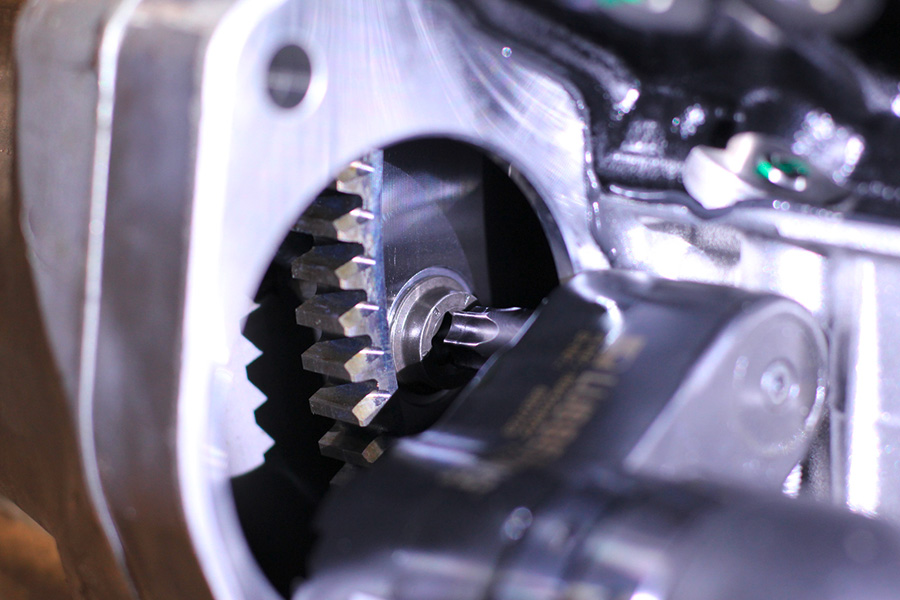

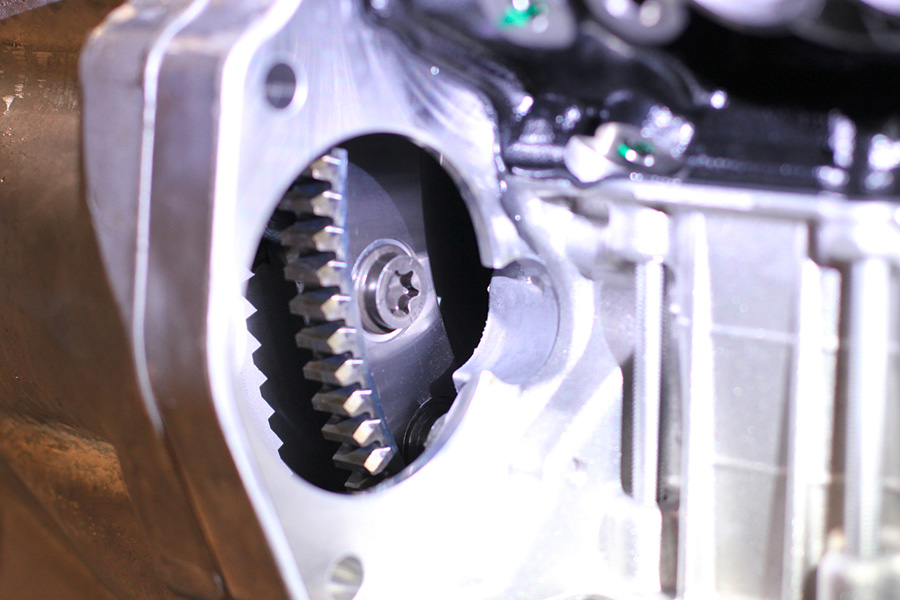

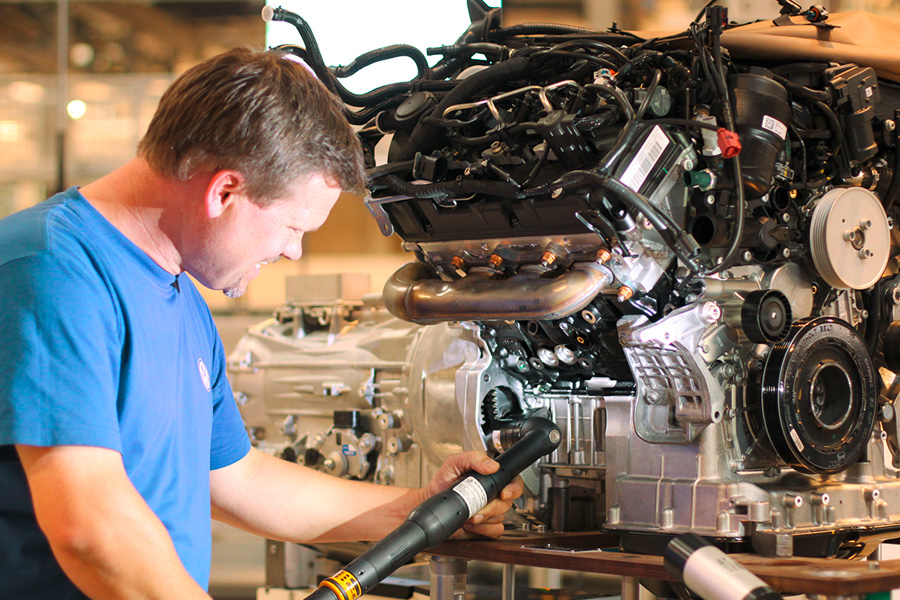

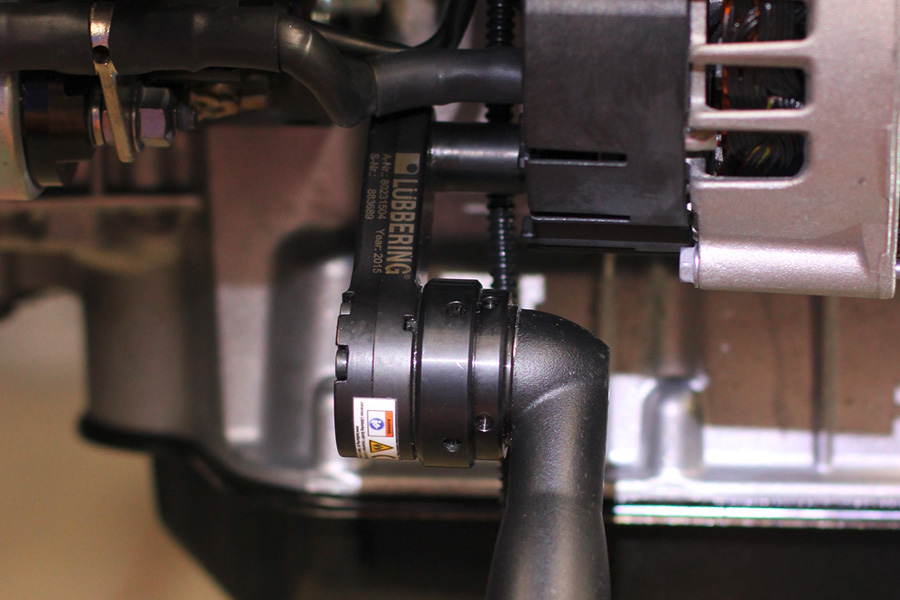

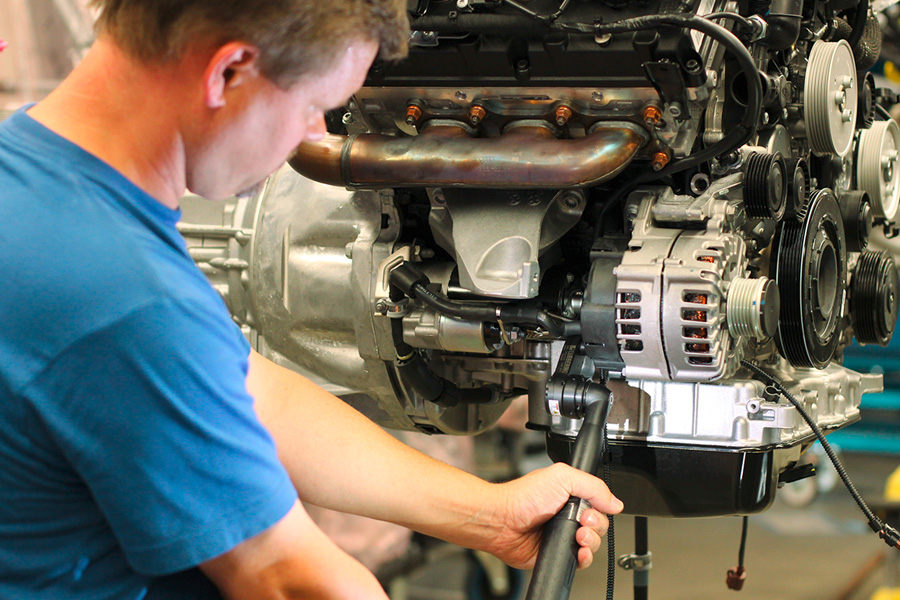

Engine

What is fastened?

- (A) Ground cable at Porsche Cayenne

- (B) Converter fastening at Porsche Cayenne

What are the difficulties?

- (A) Limited space and highest safety requirements: A-fastening

- (B) Difficult to see the fastening Position | maximum torque from minimum size of geared offset head

What is Lübbering‘s solution?

- (A) Geared offset head from our standard range

- (B) Special geared offset head is designed to provide the worker with optimum view | Geared offset head for pre- and end-tightening

back to overview

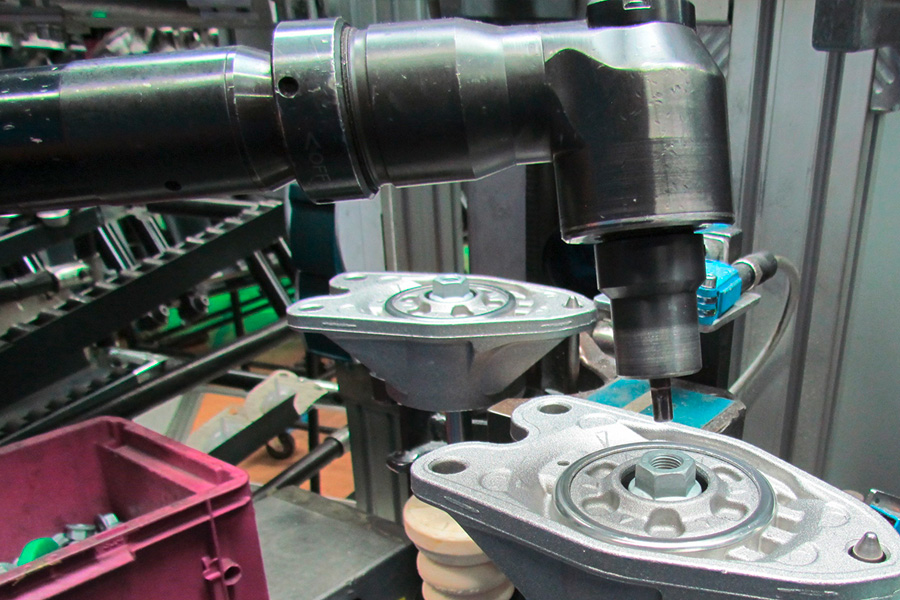

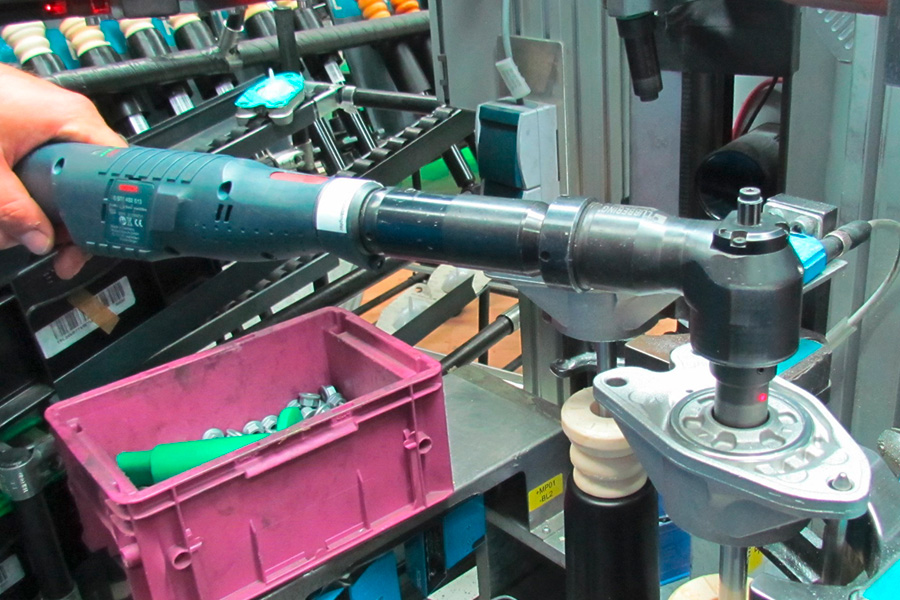

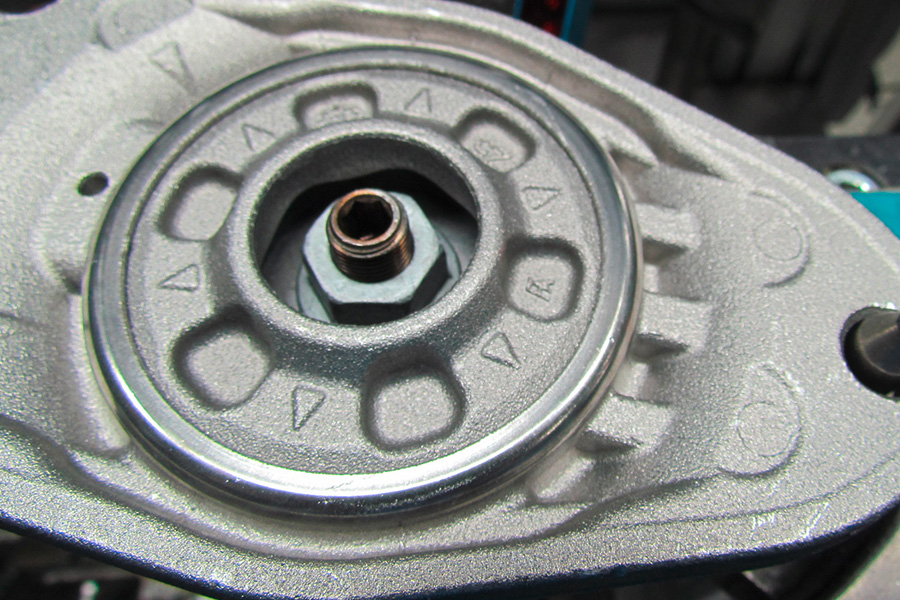

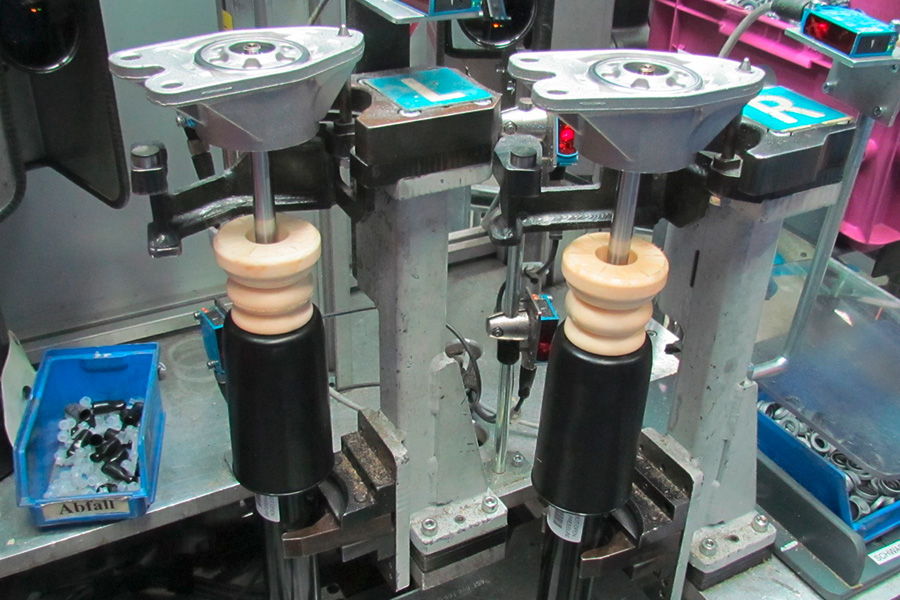

Damping rod

What is fastened?

- Damping rod with 38 Nm

What are the difficulties?

- Hold and drive is necessary because otherwise the fastened „head“ of the damping rod will twist with the suspension strut

What is Lübbering‘s solution?

- Hold and drive angle head | Fastening tool as emergency strategy with Bosch battery tool

back to overview

Fuel line

What is fastened?

- Fuel line in the engine bay / bulkhead at Porsche Cayenne

What are the difficulties?

- Limited Access

- Line must not twist during the fastening process

What is Lübbering‘s solution?

- The smallest possible geared offset head with integrated manual holder

- Compact and light design

- Minimum weight improves the handling experience of the worker