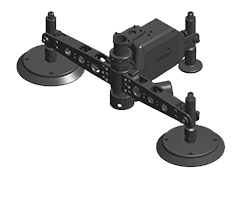

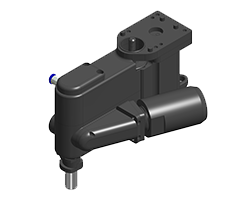

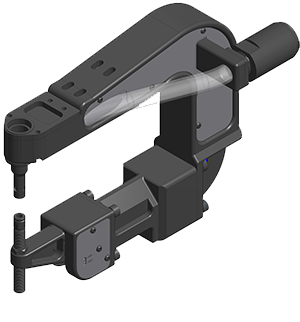

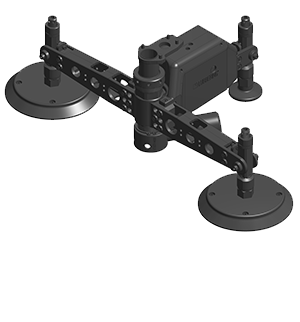

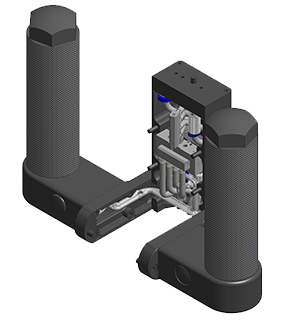

L.ADU basis

right-angled

right-angled  inline

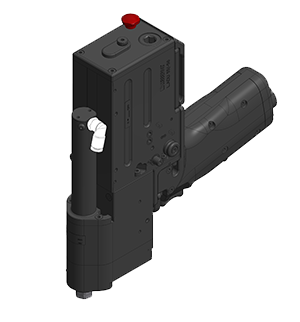

inline  grip

grip

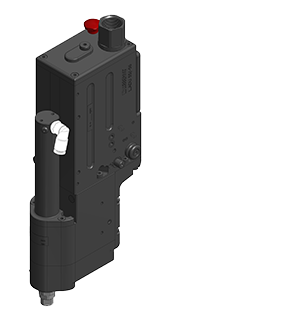

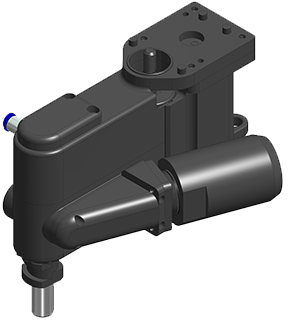

L.ADU basis right-angled

- available in 3 different motor versions: type 55, 56 and 57

- motor version type depends on required hole size and material stack

- for more power a turbine motor can also be fitted

- after selecting a suitable locking system, the machine is ready to use

L.ADU basis inline

- available in 3 different motor versions: type 55, 56 and 57

- motor version type depends on required hole size and material stack

- for more power a turbine motor can also be fitted

- after selecting a suitable locking system, the machine is ready to use

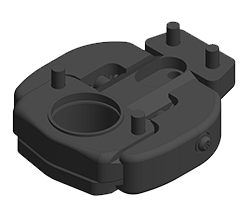

L.ADU basis grip

- available in 2 different motor versions: type 55 and 56

- motor version type depends on required hole size and material stack

- for more power a turbine motor can also be fitted

- after selecting a suitable locking system, the machine is ready to use

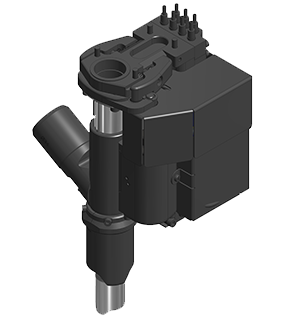

L.ADU locking systems

Concentric-Collet

Concentric-Collet  TwistLock

TwistLock  C-Frame

C-Frame  Taperlock

Taperlock  Traverse

Traverse  Geared Offset

Geared Offset

Concentric Collet (CC)

- material stacks: CFRP | titanium | aluminium

- one-shot drilling and countersinkung

- nearly 100 % chip and dust exhaust

- up to 700 N clamping force

Twist Lock

- material stacks: CFRP | titanium | aluminium

- one-shot drilling and countersinkung

- optional with chip and dust exhaust

- no clamping force

- Kann hohe Vorschubkräfte aufnehmen

- comes with an integrated Quick Change Indexing

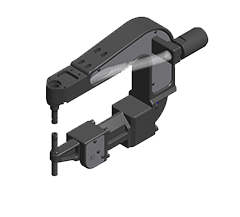

C-Frame

- material stacks: CFRP | titanium | aluminium

- one-shot drilling and countersinking

- nearly 100 % chip and dust exhaust

- up to 1.200 N clamping force

- Positioning über Pilotspitze im Gegenhalter

- Bohrwerkzeug mit Pilotspitze oder Bohrschablone

- Type P: Aufklappbarer Gegenhalter für einfache Positionierung | Materialschichtstärke: 0-100 mm

- Type J: Kein aufklappbarer Gegenhalter, Bauteilklemmung durch Parallelhub | Materialschichtstärke: 5-40 mm

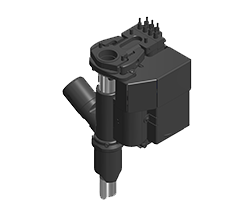

Taperlock (TPL)

- material stacks: CFRP | titanium | aluminium

- one-shot drilling and countersinkung

- nearly 100 % chip and dust exhaust

- no clamping force

Vacuum Traverse (VT)

- material stacks: CFRP | aluminium

- one-shot drilling and countersinking

- nearly 100 % chip and dust exhaust

- up to 1.000 N clamping force

Geared Offset (GO)

- material stacks: CFRP | titanium | aluminium

- one-shot drilling and countersinking

- optional with chip and dust exhaust

- no clamping force

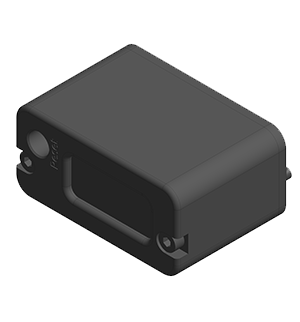

L.ADU options

Circle-Counter

Circle-Counter  MQL-System

MQL-System  Sine-Feed

Sine-Feed  Quick Change System

Quick Change System  Quick Change Indexing

Quick Change Indexing  Two-Hand-Grip

Two-Hand-Grip

Cycle Counter

- Counts the drilling cycles

- Digital LED display

- Preventive maintenance due to drill cycle information

- Reset the counter with the magnetic pin

MQL System

- For perfect drilling and surface quality

- Highest quality of coolant

- Constant feed of micro drops

- Quantity of coolant can be individually adjusted

- Easy to refill

Sine-Feed

- Lübberings Mirco-Peck solution Sine-Feed breaks the long chips into micro chips

- Micro chips for perfect drilling quality

- Lübberings Sine-Feed is even possible with one-shot drilling and countersinking

- The name "Sine-Feed" stands for sine like spindle vibrations

- Will be assembled into the basis machine

- Also with MQL System possible (dry cutting)

Quick Change System

- Quick changeover of locking systems due to uniform interface

- Good access to the cutting tool (e.g. for cleaning)

- Low risk of damaging the cutting tool

Quick Change Indexing

- Quick exchange of locking systems with the integrated Quick Change System

- Additional value: 360° rotation of the machine

- Just pull, turn and release - and the machine is locked in the desired position

- Easy and comfortable handling

Two-hand grip

- Two-hand gip - ideal for overhead work

- Available for inline version of the basis machine

L.ADU pneumatic – modular standard program

- Can be individually configurated thanks to the modular structure

- The outcome of 3 basis machines, 6 locking systems und 6 additional options is over 100 different possible combinations

- Depending on the drilling size and process there are different models (right-angled, inline, grip) and motor types (type 55, 56, 57) available

- The basis machine (L.ADU basis) is together with the locking system (L.ADU locking system) ready to use

- The modular concept offers comfortable additional options (L.ADU options)

- The locking systems can be changed quickly and easily due to a uniform interface (L.ADU Quick Change System)

- Low maintenance: Minimum requirement of wear and spare parts (< 10%)

- Optimised Drilling Quality: no delamination in CFRP - burrless drilling

- Enormous time saving thanks to one-shot drilling and countersinking

Video zu L.ADU pneumatic